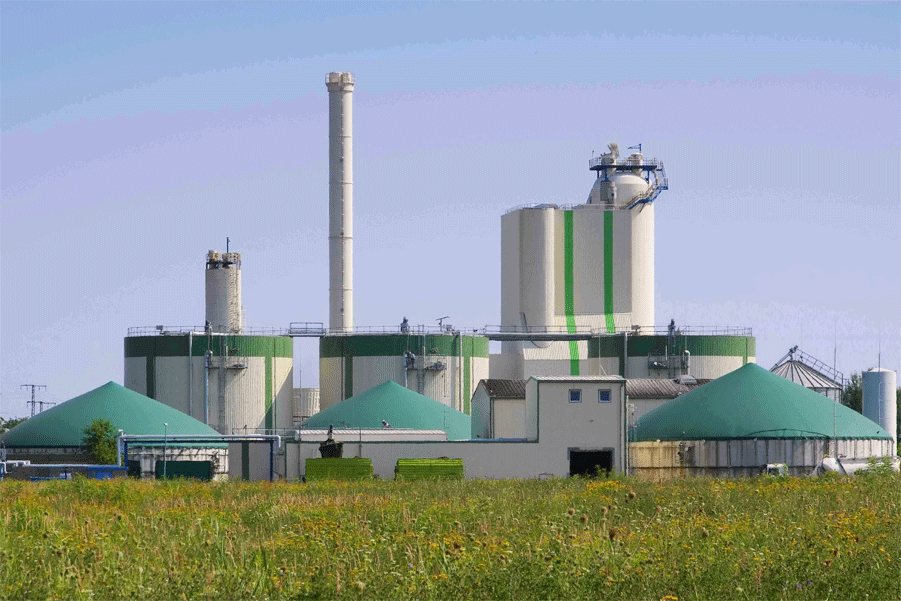

Greentree Landfill RNG Facility

Kupper Engineering provided full electrical engineering and mechanical engineering services, as well as a complete control system for the new hydrogen sulfide (H2S) removal system and ancillary equipment at the Greentree Landfill’s 4000 scfm renewable natural gas (RNG) facility. Our team procured the motor control center and provided coordination of implementing the new equipment with the existing equipment. Kupper also designed and built a custom system control panel and integrated the new system into the existing control system and SCADA. Our systems integrators provided startup and commissioning support for the project.

Greentree Landfill RNG Facility Read More »